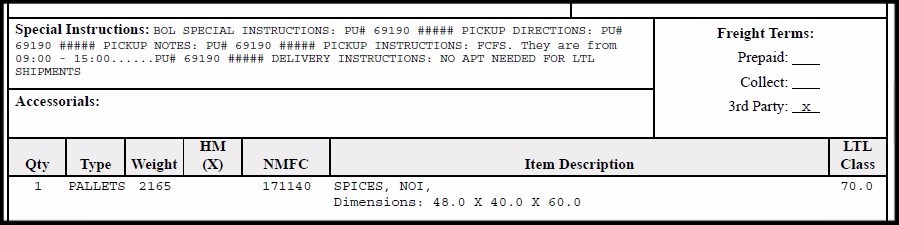

It is VERY important you understand freight class. If you incorrectly classify your item to be shipped it can be reclassified by the freight carrier. Disputing this is difficult, time consuming and you will be charged the difference (usually without a discount).

The

National Motor Freight Classification® (NMFC®) is a

standard that provides a comparison of commodities moving in interstate,

intrastate and foreign commerce. Commodities are grouped into one of 18

classes—from a low of class 50 to a high of class 500—based on an evaluation of

four transportation characteristics: density, stow-ability, handling, and

liability. Together, these characteristics establish a commodity’s

“transportability.”

By analyzing commodities on the basis of the four transportation

characteristics and ONLY on the basis of those characteristics, the NMFC

provides both carriers and shippers with a standard NMFC number or code by

which to begin negotiations and greatly simplifies the comparative evaluation

of the many thousands of products moving in today’s competitive marketplace.

If you don’t have an NMFC number/code listed on your BOL, there is a good possibility that your freight will be reclassified. Some carriers will assign an arbitrary class if there is no code listed on the BOL, often outlined in a carrier’s rules tariff. This, along with the proper code, will greatly reduce the possibility of additional reclass charges.

Don’t forget we are participants of the National Motor Freight Traffic Association which means we have access to multiple ways of obtaining the correct NMFC number/code for your shipments. If you have any questions or doubts regarding your product’s freight class, please reach out to the LTL Team.